Medical Health & Safety

Pressure and temperature instruments to help health and safety equipment operators measure and monitor system conditions

When talking about medical, health, and personal safety equipment, the health and safety of end-users are paramount. Over the years, this focus has led to increasing demand for better equipment performance (e.g., better accuracy or reliability). As a result, measurement and control instrument manufacturers have been challenged to create products that offer better and better performance to ensure the various devices and systems in which they are installed function as effectively and efficiently as possible.

At Ashcroft, our pressure and temperature instruments are suitable for use in a broad selection of medical, health, and personal safety equipment, including the following:

Safety shutoff, pressure and temperature control, sterilizer "opening" conditions verification for operator safety, patient breathing monitoring and verification

Flow control, measurement and verification

Positive or negative room pressure control, monitoring and verification, airflow control and monitoring, and HEPA filter monitoring

Breathing air pressure monitoring and low pressure indication, fire suppressant system pressure monitoring, and building water pressure verification

Importance of Pressure and Temperature Instruments for Medical Health and Safety Equipment

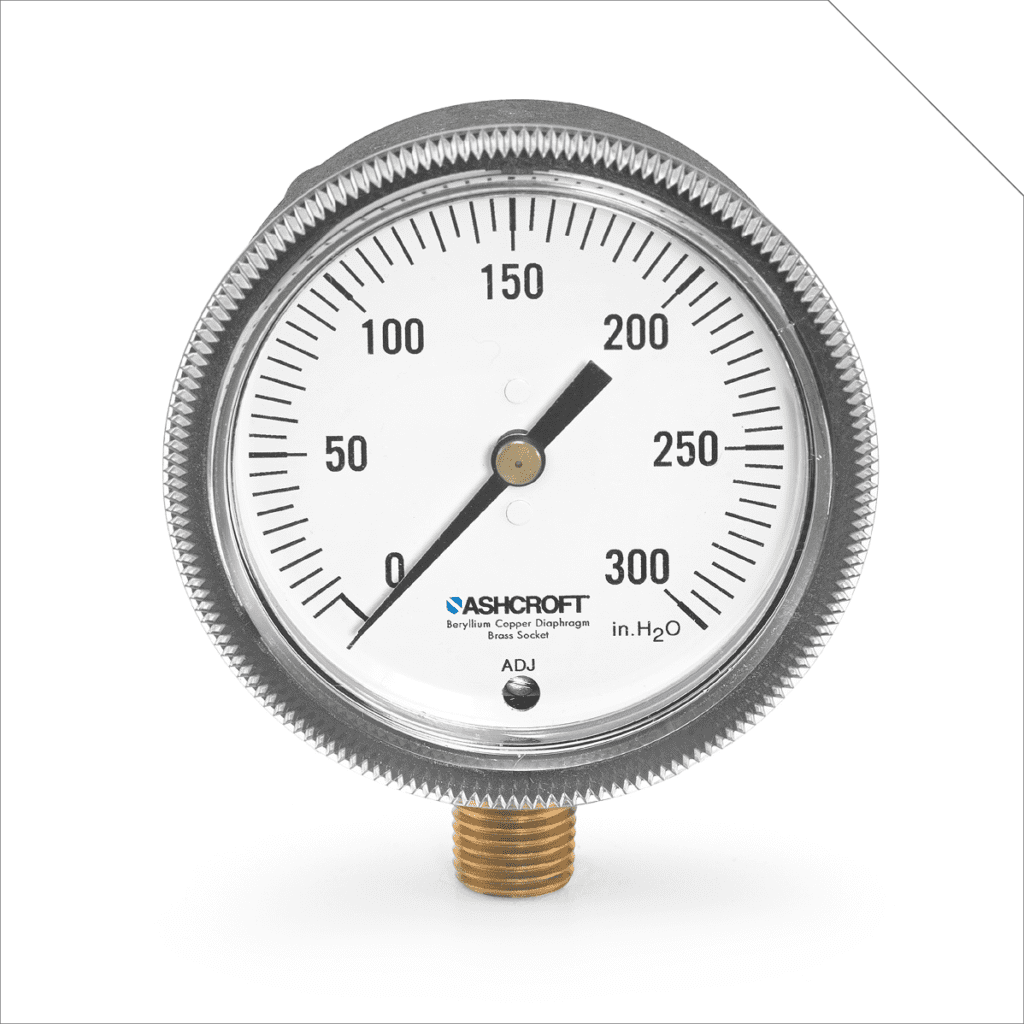

As indicated above, medical, health, and personal safety equipment must be designed and built to ensure the health and safety of end-users. The instruments integrated into such equipment—such as pressure or temperature transducers, gauges, and switches—help equipment operators measure and monitor system conditions to ensure they remain within a safe range. However, they must meet demanding performance requirements—particularly with regard to accuracy, reliability, and longevity—even under harsh environmental and operating conditions. Additionally, given the sensitive or critical nature of such equipment, they must accommodate sanitary requirements to ensure the application area remains free from contamination.

Ashcroft: Protection for What Matters Most

At Ashcroft, we design and manufacture a variety of pressure and temperature instruments—such as transducers, gauges, and switches—suitable for use in medical, health, and personal safety equipment. By working closely with equipment manufacturers, we engineer measurement and control solutions that ensure equipment is safe for end-users (e.g., medical professionals and patients, military personnel, miners, and rescue workers) and compliant with industry and regulatory standards (e.g., 3-A Sanitary and Mil-Spec).

Why Partner with Ashcroft?

Ashcroft is a premier source of quality instrument solutions for the medical, health, and personal safety equipment industries and beyond. By choosing us as your partner for your instrumentation needs, your benefit from our:

All of our instruments are carefully researched, developed, manufactured, and tested to ensure they maintain consistent performance even in some of the most challenging environments. We also offer our patented ATE-2 Handheld Calibrator, a portable testing and calibration instrument for temperature and pressure sensors, gauges, and switches, to help equipment manufacturers verify and ensure the performance of a unit

We subject our products to extensive testing operations—including environmental, shock/vibration, temperature, and EMI/RFI testing—to ensure they fully comply with all relevant customer specifications and industry standards.

Our team follows a dedicated review process to ensure the solution we provide fully accommodates customer specifications, including with regard to private labeling requirements.

Our products are approved by/comply with a variety of national and international standards, including ISO 9001, 3-A Sanitary, ATEX/IECEx, CE, UL, FM, CSA, CRN, and SIL.

Our instruments are engineered for accuracy and reliability. They ensure equipment runs effectively and efficiently (saving customers on operating costs) and withstand use in rugged environments (saving customers on repair and replacement costs).

Trust in the Ashcroft Experts

At Ashcroft, we are here to help you identify the right measurement and control solution for your equipment manufacturing needs. For product solutions that integrate with your equipment, trust us to put our industry experience, engineering knowledge, and can-do attitude to work for you.