Compliant ready instruments for hygienic manufacturing

Protect your process, easy-to-validate pressure and temperature measurements.

View Products Select the Right SolutionManage the risks of pharma & biotech operations

Contamination Control

Use sanitary instruments designed for Clean-in-Place (CIP), Sterile-in-Place (SIP) operations help protect sensitive processes in sterile environments.

Pressure Stability

Ensure precise measurements and long-term repeatability

Validation & Compliance

Ensure optimal low-pressure conditions with differential pressure sensors featuring in-place calibration.

Batch Process Reliability

Select high-accuracy pressure gauges and isolation devices to ensure consistent conditions for automated processes.

Equipment Protection

Detect abnormal conditions and trigger alarms with pressure switches and transmitters to prevent costly damage.

Pressure and temperature instruments built for hygienic applications

Your trusted source for pharmaceutical and biotech measurement and control instruments

Since 1852, Ashcroft has been designing, engineering and manufacturing high-quality measuring, monitoring and control instruments that offer accuracy and reliability while meeting strict regulatory standards.

We understand your business. With extensive industry experience and a broad product selection, Ashcroft provides reliable pressure and temperature solutions you need to ensure safe and compliant operations.

View Products Select the Right Solution

Strengthen cleanroom performance with a recognized leader.

Experienced Partner

Gain industry insights to help with your product selections to ensure safe and efficient operations.

High Quality Products

Find the best pressure and temperature instruments to meet the stringent requirements for your pharma and biotech applications.

Efficient Processes

Benefit from our streamlined operations including in-house design, engineering, manufacturing, testing, calibration and certification.

Ongoing Support

Access product expertise through our in-house technical team, products specialists or our global partner network.

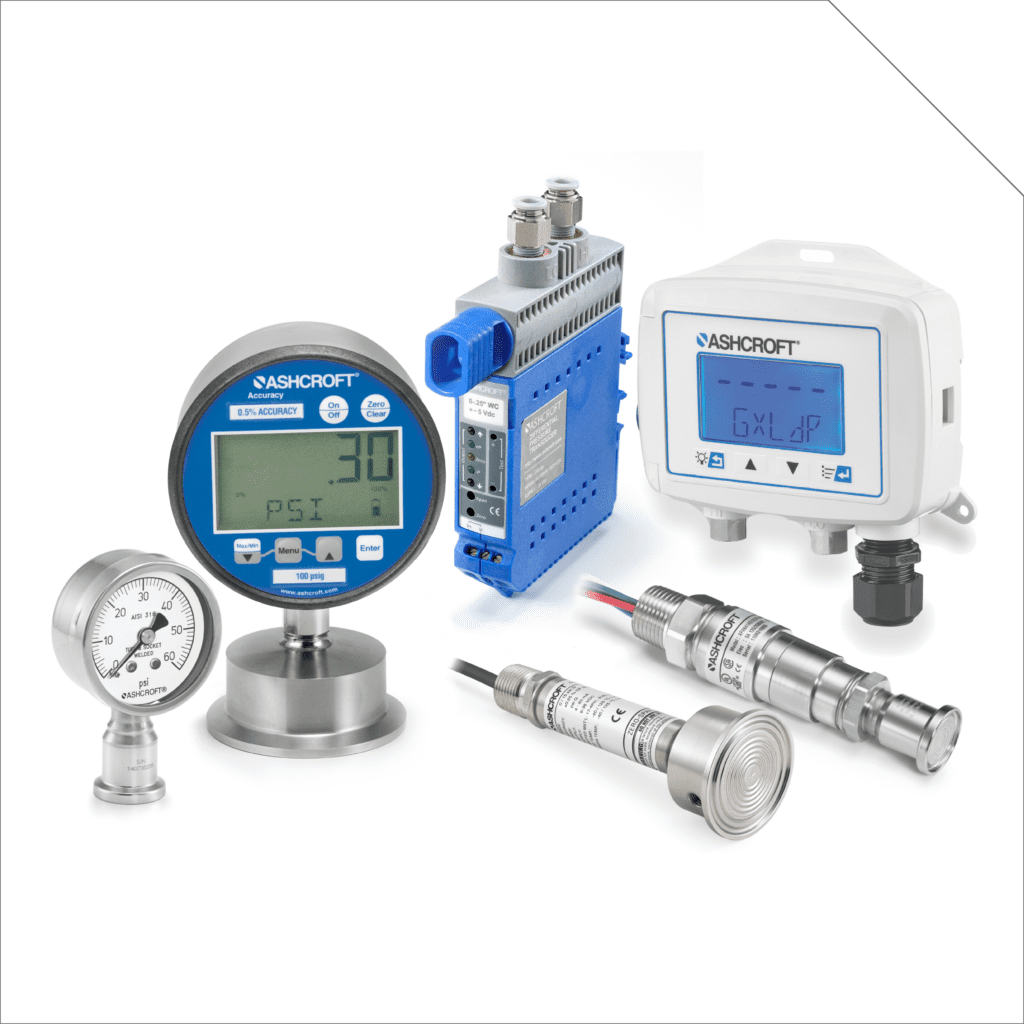

Reduce downtime with in-place calibration

In critical cleanroom environments, taking sensors offline can cause costly downtime. The Ashcroft SpoolCal™ Actuator on the DXLdp and GXLdp pressure transducers enables accurate in-place calibration without disconnecting the sensor, saving time and reducing the risk of contamination.

View Products Learn More

Find pressure and temperature instrumentation for your specific applications

Explore compatible products for your operation.

Discuss your product and application requirements.

Ensure you receive all the components you need.

Where you’ll find Ashcroft instruments

Ashcroft pressure and temperature instruments can be found in multiple stages of pharmaceutical and biotechnology operations, providing measurement and control solutions that protect product integrity and ensure compliance.

Maintain stable pressure to protect against sterility breaches and safeguard contamination-free environments.

Support SIP/CIP, autoclaves and sterile production lines with sanitary, easy-to-clean designs.

Precisely measure and control ultra-low differential pressure to protect operators and processes.

Deliver consistent process conditions for reliable results in complex formulations.

Verify Compliance with Hygienic Assurance

For hygienic and other high-integrity applications, knowing where your materials come from is essential. Ashcroft offers material traceability documentation for select instruments, providing verified records of material origin to support quality and compliance.

Note: Material traceability is not available for products such as pressure switches and transducers.

Understand the key considerations involved in working with pharmaceutical and biotechnology systems.

Solve your toughest pharmaceutical & biotech challenges

Download our guide to learn strategies for maintaining sterile conditions, meeting regulatory demands and protecting product integrity. Plus, get expert recommendations for selecting the right instrumentation to support cleanroom and hygienic processes.

Be confident in your cleanroom system performance.

Speak to an industry expert to learn how to ensure safety and efficiency for your applications.