Proven pressure & temperature instruments for optimal hydrogen system performance

Be confident about hydrogen safety and compliance challenges with trusted and reliable solutions for an industry leader.

View Products Avoid Hydrogen HazardsSolutions for hydrogen's toughest challenges

Working with hydrogen is dangerous. Ashcroft's trusted expertise, proprietary technology and field-proven solutions ensure your systems meet the highest safety and quality standards.

Explosion & Fire

Minimize risk with E2F Explosion-proof/Flameproof and E2S Intrinsically Safe Pressure Transducers that safely contain and vent energy through the flame path.

High Temperature

Maintain safe and reliable temperature measurements with instruments like the S50 RTD, S50 Thermocouple and 316L Thermowell.

Embrittlement & Permeation

Mitigate risk using instruments with 316L and A286 wetted materials like the E2F/E2S Pressure Transducers offering a tight lattice structure to withstand prolonged exposure to hydrogen.

Get hydrogen-compatible instrumentation to meet industry safety and compliance demands

Confidently navigate hydrogen market complexities

With decades of experience, Ashcroft will help you meet regulatory demands and ensure optimal performance of your hydrogen systems with tailored solutions.

Experienced Partner

Receive hydrogen-specific guidance from a trusted leader in pressure and temperature instrumentation.

High Quality Products

Find the best solution that can meet the challenging conditions and standard requirements of your hydrogen applications.

Efficient Processes

Benefit from streamlined operations including in-house design, engineering, manufacturing, testing, calibration and certification.

Ongoing Support

Access product expertise through our in-house technical team, product specialists, or our global partner network.

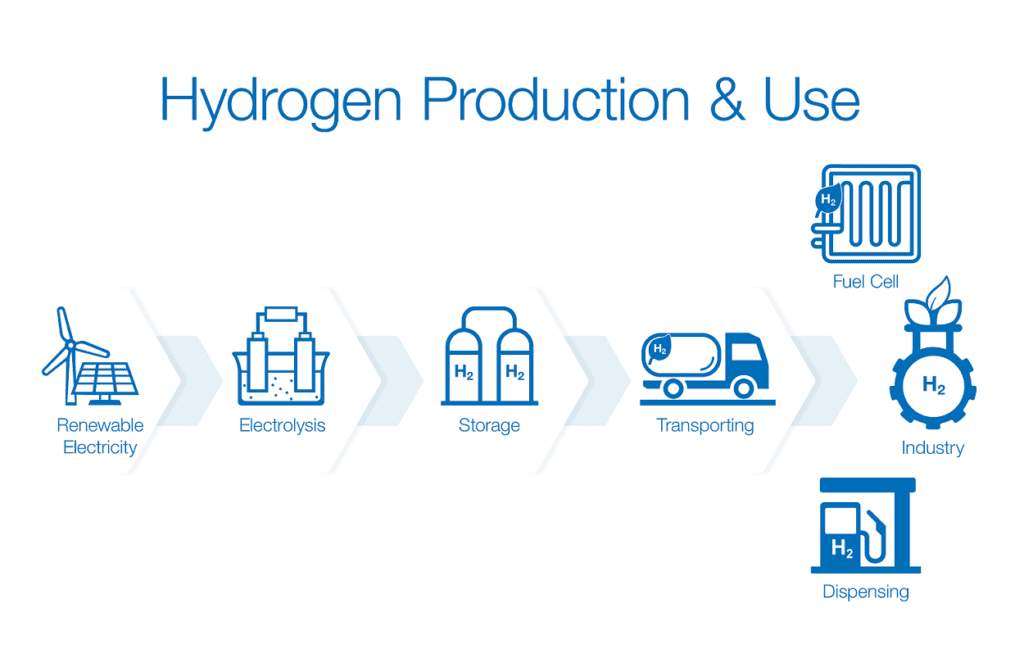

Hydrogen-ready solutions for each stage of the hydrogen process.

When you partner with a hydrogen instrument expert, you get guidance at every stage, from product configuration to delivery and beyond to help you choose the most reliable, compatible and safe solution for your specific needs.

View Products Avoid Hydrogen Hazards

Cleaning for Oxygen Service

Cleaning for oxygen is avaible for most Ashcroft instruments used in high-purity applications such as hydrogen piping system, compressed hydrogen storage, fuel cells and more. The service ensures your instruments are free of contaminants like dust, oils and lingering residue that can easily ignite and burn with intensity.

View Products Read Article

Where you’ll find Ashcroft instruments

Customers use Ashcroft products in many hydrogen systems and processes because they trust their safe and reliable performance.

Petroleum Refining - Hydrocracking

Fuel Cells & Fueling Stations

Semiconductor Manufacturing

Fertilizer and Ammonia Production

Hydrocracking is a two-stage process that combines catalytic cracking and hydrogenation to process feedstocks that are challenging for traditional catalytic cracking or reforming. Operating under high pressure and high temperature with hydrogen and a catalyst, this process takes place in hazardous environments. Ashcroft offers pressure instruments that meet explosion-proof, intrinsically safe or non-incendive hazardous location approvals, making them ideal for these applications.

Hydrogen powers fuel cells and fueling stations by reacting with oxygen to produce electricity—emitting only water. It’s produced via electrolysis, compressed, and stored for delivery at 350 or 700 bar. Ashcroft’s pressure and temperature instruments ensure system accuracy and safety throughout production, storage, and fueling, supporting clean energy for vehicles and backup power applications.

Hydrogen is utilized in semiconductor manufacturing

primarily for its reducing or oxygen scavenging properties. It is also an extremely effective heat transfer fluid, which is an advantageous property in some operations. Some of the semiconductor manufacturing operations in which it is used include: semiconductor sintering, semiconductor packaging and wafer annealing.

Hydrogen is essential in fertilizer and ammonia production, serving as a feedstock in the Haber-Bosch process, which synthesizes ammonia to deliver nitrogen to crops. The reaction uses an iron catalyst under high pressure to boost yield. For reliable operation, choose pressure and temperature instruments with high-pressure capability, corrosion resistance and long-term stability to ensure safety and process efficiency.

Explore helpful content to understand the key considerations involved in working with hydrogen alternative energy.

Choosing a Pressure Gauge for Hydrogen Applications (resource)

What are Safe Temperature Sensors for Hydrogen Applications? (resource)

Choosing Pressure Transducers for Hydrogen and Hazardous Locations (resource)

Pressure and Temperature Instrumentation in Hydrogen Systems Guide (resource)

How Are Pressure Transducers Affected by Hydrogen Permeation? (resource)

Find pressure and temperature instrumentation for your hydrogen alternative energy systems

Explore hydrogen-compatible products for your operation.

Discuss your product and application requirements.

including samples, supporting documentation and testing.

to ensure you receive all the components you need.

Master hydrogen safety today.

Ready to learn more? Download our guide to gain critical insights about the hazards of hydrogen and how to select the right instrumentation to ensure the safety of your people and operations.

Be confident in your hydrogen system performance.

To speak to an industry expert, contact us to learn how to ensure safety and efficiency for your hydrogen systems.